CORE ADVANTAGES

Special product features and advantages are worthless without a tangible effect. The effect of VOMO’s core advantages can be simply reduced to one thing: economic efficiency. The core advantages of VOMO products translate into economic benefits for VOMO customers, directly contributing to customer value. Whether these economic benefits for customers and partners are realized primarily through cost savings in procurement, process optimization through the

implementation of new products, improvements in storage, logistics, and transportation, or simply in the optimization of time and labor, is highly individual.

Weight Reduction

The fundamental characteristic of all VOMO products is their relatively extremely low weight. This significant weight advantage, combined with exceptional dimensional stability, makes the lightweight honeycomb panels truly unique.

The comparison with conventional materials in these market segments makes this clear!

Save Weight – Create Value

This obvious weight reduction results in significant savings potential—both financially and in terms of time. Lower transportation costs are achieved through reduced fuel consumption. The reduction in labor and assembly effort frees up time for additional projects. Fewer damages during storage and logistics reduce the need for replacements, and, last but not least, it protects the health of those working with the material. Saving weight means saving time, making efficient use of capital, and working in an environmentally friendly manner with sustainability in mind.

Weight Reduction

The fundamental characteristic of all VOMO products is their relatively extremely low weight. This significant weight advantage, combined with exceptional dimensional stability, makes the lightweight honeycomb panels truly unique.

Save Weight – Create Value

This obvious weight reduction results in significant savings potential—both financially and in terms of time. Lower transportation costs are achieved through reduced fuel consumption. The reduction in labor and assembly effort frees up time for additional projects. Fewer damages during storage and logistics reduce the need for replacements, and, last but not least, it protects the health of those working with the material. Saving weight means saving time, making efficient use of capital, and working in an environmentally friendly manner with sustainability in mind.

Sustainability

Sustainable thinking and actions form the foundation of our future, especially when processing natural raw materials. For VOMO, the concept of sustainability applies not only to the use of products but also to their manufacturing.

… in production

A large-scale photovoltaic system and a heating concept based on the use of waste wood chips form the foundation of VOMO’s energy use in both manufacturing and administration. With the construction of the new facility in 2009, a sustainable and nearly energy-independent concept was successfully implemented.

… in transport

Significant weight savings have positive effects on transportation. Fuel consumption and CO² emissions are inevitably linked to material weight—factors that are significantly reduced by using VOMO lightweight elements. Additionally, empty volumes due to excessive load weight are avoided.

… in the product

Honeycomb technology based on nature’s design: The highly stable honeycomb core, which typically makes up over 70% of a VOMO lightweight element, is made from 100% recycled and FSC-certified waste paper. This paper honeycomb core is the foundation for all VOMO products!

… in application

VOMO products are designed with the goal of maximizing reusability. The high product quality ensures long-term use. The conceptual modularity of the core products conserves resources and reduces the frequency of reorders and additional purchases.

Modularity

At VOMO, special attention is given to the modularity and combinability of individual elements when developing product lines and components. The design of standard versions of products, such as wall systems or furniture, already takes this combinability into account. Furthermore, this approach minimizes material usage and enhances the customer’s options in procurement and storage.

Particularly in the fields of museum and exhibition design, as well as in the trade show and event equipment segments, modular concepts offer enormous advantages. Wall configurations or furniture can be reused from existing inventory, room layouts can be quickly altered, and inventory can be supplemented and expanded with minimal additional purchases. This is a concept that works in the long term and allows for highly flexible operations.

Of course, modular system concepts do not always provide a comprehensive solution for every project requirement. That’s why VOMO consistently looks beyond standard solutions, offering customized interfaces, designs, and approaches. VOMO strikes the right balance between modular standards and flexibility—all while maintaining a lightweight structure.

Modularity

At VOMO, special attention is given to the modularity and combinability of individual elements when developing product lines and components. The design of standard versions of products, such as wall systems or furniture, already takes this combinability into account. Furthermore, this approach minimizes material usage and enhances the customer’s options in procurement and storage.

Particularly in the fields of museum and exhibition design, as well as in the trade show and event equipment segments, modular concepts offer enormous advantages. Wall configurations or furniture can be reused from existing inventory, room layouts can be quickly altered, and inventory can be

supplemented and expanded with minimal additional purchases. This is a concept that works in the long term and allows for highly flexible operations.

Of course, modular system concepts do not always provide a comprehensive solution for every project requirement. That’s why VOMO consistently looks beyond standard solutions, offering customized interfaces, designs, and approaches. VOMO strikes the right balance between modular standards and flexibility—all while maintaining a lightweight structure.

Flexibility

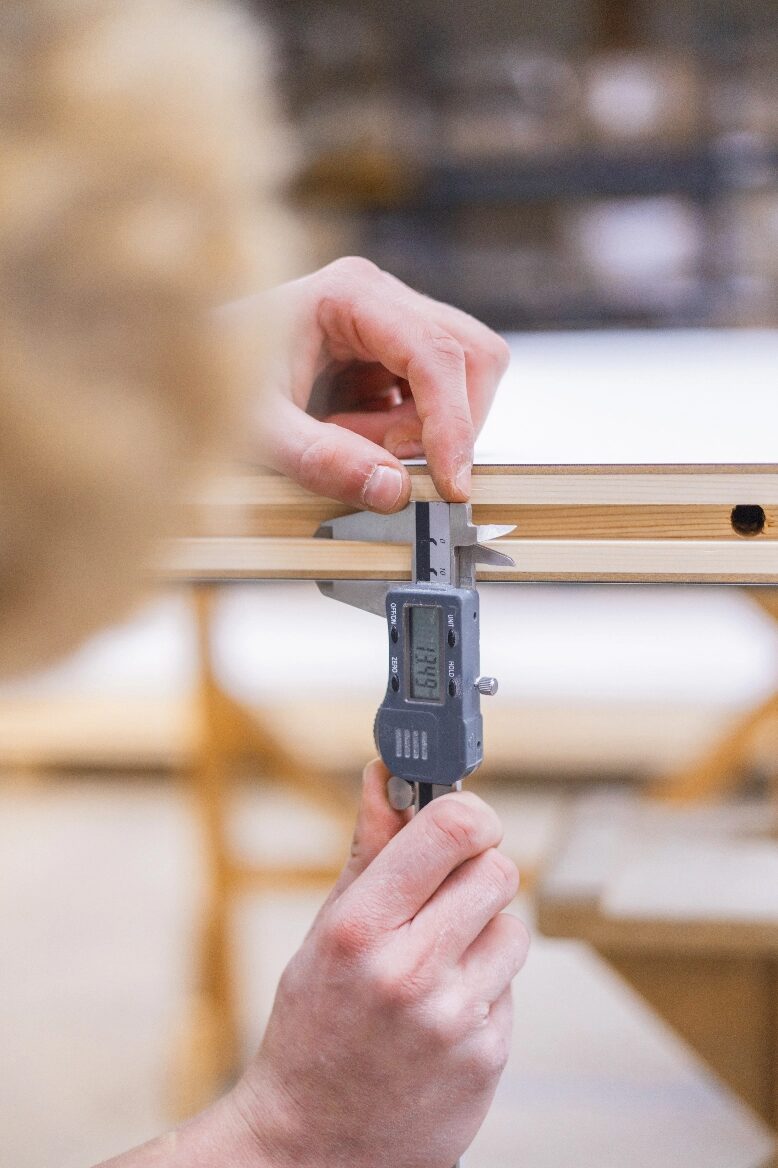

Every day, it is essential to respond quickly and flexibly to a wide range of project requirements. VOMO supports its customers from the project phase onward, working together to develop the best possible solution for each individual lightweight construction project. The high level of in-house production capability enables this flexibility.

… in format

Technically up-to-date, VOMO’s production capabilities not only allow for large output volumes but also enable the manufacturing of very large formats while maintaining low weight. This is a clear distinction from standardized industrial production, which often does not accommodate special cases.

… in production

The technical range of production not only allows for pressing all available market decors and veneers onto the desired lightweight elements but also offers a wide variety of processing options for these elements. Two highly specialized CNC centers enable customized processing based on customer specifications, resulting in a final product that is 100% tailored to the customer’s project requirements.

… in quantity

On average, VOMO produces around 1,000 lightweight elements per week in standard operations. This enables the production to quickly deliver large quantities. However, order acceptance is not limited to large batch sizes; small quantities or individual orders are also possible at VOMO. This flexibility makes it easier for VOMO’s customers and partners to manage purchasing calculations and inventory.

Flexibility

Every day, it is essential to respond quickly and flexibly to a wide range of project requirements. VOMO supports its customers from the project phase onward, working together to develop the best possible solution for each individual lightweight construction project. The high level of in-house production capability enables this flexibility.

… in format

Technically up-to-date, VOMO’s production capabilities not only allow for large output volumes but also enable the manufacturing of very large formats while maintaining low weight. This is a clear distinction from standardized industrial production, which often does not accommodate special cases.

… in production

The technical range of production not only allows for pressing all available market decors and veneers onto the desired lightweight elements but also offers a wide variety of processing options for these elements. Two highly specialized CNC centers enable customized processing based on customer specifications, resulting in a final product that is 100% tailored to the customer’s project requirements.

… in quantity

On average, VOMO produces around 1,000 lightweight elements per week in standard operations. This enables the production to quickly deliver large quantities. However, order acceptance is not limited to large batch sizes; small quantities or individual orders are also possible at VOMO. This flexibility makes it easier for VOMO’s customers and partners to manage purchasing calculations and inventory.

Weight Savings

Sustainability

Modularity

Flexibility

The secret is inside